Anwendungsbeispiele für Säulenschaltungen

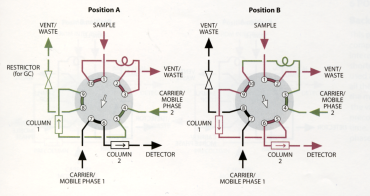

These illustrations show basic sample injection techniques using Valco two position valves. With rare exceptions, there is no difference between switching valves and external volume sampling valves, so the same valve can be used for eitherfunction.The unique advantage of 8 and 10 port valves is that they reduce extra column volume by combining sampling and switching functions in a single valve. This minimizes expense, maintenance, service, and risk of leaks as compared to multiple 6 port valve systems.

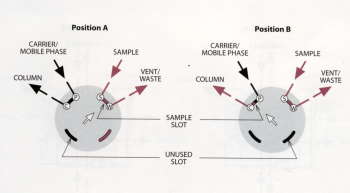

| 4 PORT

INTERNAL SAMPLE INJECTOR Microvolume Sample Injection The internal sample (fixed volume) flowpath is used when very small sample volumes are required. The sample size is determined by a passage engraved on the valve rotor, allowing precise, repeatable injections. In Position A, the sample flows through the sample passage while the mobile phase flows through to the column. The third passage is inactive. In Position B, the sample passage is in line with the column and the mobile phase injects the contents of the sample passage onto the column.The passage which was inactive in Position A allows the sample to continue flowing without interruption. |

|

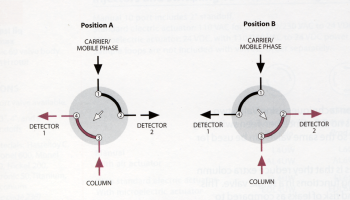

| 4 PORT

SWITCHING VALVE Detector Selection from Two Columns or One Column and Auxiliary Carrier This unique configuration allows analysis of different parts ofone analysis with two different detectors, without splitting or multiple injections. For example, fixed gases can be analyzed with a thermal conductivity detector,followed by the analysis of a hydrocarbon fraction with a flame ionization detector. |

|

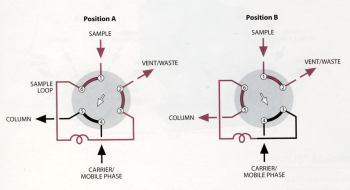

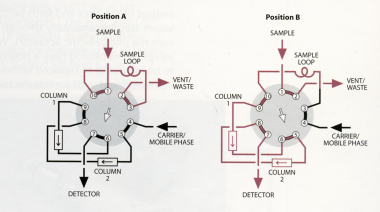

| 6 PORT

EXTERNAL SAMPLE INJECTOR Sample Injection With the valve in Position A, sample flows through the external loop while the mobile phase flows directly through to the chromatographic column. When the valve is switched to Position B, the sample contained in the sample loop and valve flow passage is displaced by the mobile phase and is carried onto the column. Note: This is especially critical for partiallyfilled loops. The flow direction of the mobile phase through the loop should be opposite (backflush) to the flow direction during the loading of the loop. |

|

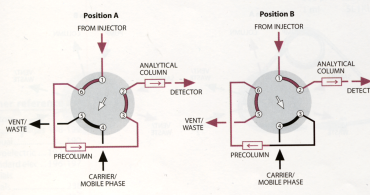

| 6 PORT

COLUMN SWITCHING Backflush of Precolumn to Vent This plumbing scheme allows slower eluting components (end cut) which are not of interest to be backflushed to vent. Often a shorter version of the analytical column is used as the precolumn. Once all the components of interest have entered the main column (at port 2), the valve switches, backflushing the precolumn to vent and reducing analysis time. An auxiliary source of carrier or mobile phase is required forthis application. |

|

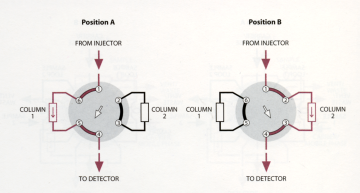

| 6 PORT

COLUMN SELECTION Two Column Selection When two different columns are required at frequent intervals at similar oven temperatures, a 6 port valve can provide rapid selection of the one to be used. The column not in use is protected by a blanket of inert mobile phase and may be rapidly brought to equilibrium when required. (If flow must be maintained to the nonselected column, an 8 or 10 port valve is required.) |

|

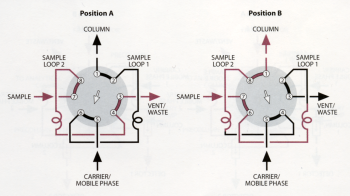

| 8 PORT DUAL

EXTERNAL SAMPLE INJECTOR Same Sample to Different Loops In a dual external sample loop config-uration, sample is injected in both positions. In Position A, Loop 2 is loaded while the mobile phase flows through Loop I and onto the column. In Position B, the Loop 2 sample is injected into the column and another sample is loaded into Loop 1. When the valve is returned to Position A, the Loop 1 sample is injected onto the column and Loop 2 is reloaded. |

|

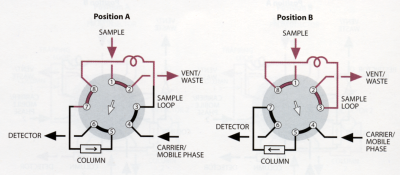

| 8 PORT

SAMPLING/SWITCHING Loop Sampling with Backflush to Detector One valve functions as sampling and backflush valve, simplifying operation and reducing cost. When components of interest are detected, the strongly retained components are backflushed and removed from the column without temperature programming. |

|

| 10 PORT DUAL

EXTERNAL SAMPLING Two Different Samples to Same Column A 10 port valve permits alternate injections from the two loops, which may be identical or of different sizes. This technique replaces a 4 port switching valve, used as a sample selector,and a 6 port sample injector. In Position A, Loop 2 is loaded with sample 2 while the mobile phase flows through Loop 1 and onto the column. In Position B, the Loop 2 sample is injected onto the column and Loop 1 is loaded with sample 1. When the valve is returned to Position A, the Loop 1 sample is injected onto the column and Loop 2 is reloaded with sample 2. |

|

Simultaneous Injection of the Same Sample onto Separate Columns In Position A, sample fills the two loops in series. In Position B, the sample is simultaneously injected into two separate flow systems. A single autosampler used with this flowpath can automate two analytical procedures for the same sample. In an important non-chromatographic application,the roles of carrier and sample are reversed, permitting two different quantities of two different materials to be dispensed together, as in automatic dilution. |

|

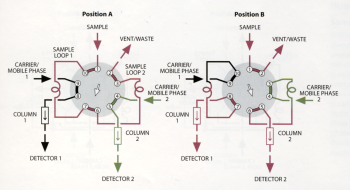

| 10 PORT

SAMPLING/SWITCHING Loop Sampling with Backflush of Pre-column to Vent When components of interest are low boiling,this plumbing scheme allows"heavy" components with long retention times to be backflushed to waste. After the sample loop is loaded in Position A, the valve is switched to Position B to inject the sample onto column 1. As soon as all components of interest have entered column 2, the valve is switched back to Position A. Column 1 is backflushed to vent during the analysis, reducing the total analysis time. |

|

| 10 PORT

SAMPLING/SWITCHING Loop Sampling with Two Column Sequence Reversal This is ideal for fixed gas-from-CO, analysis where no"high boilers"are present. Column 1 is packed with a porous polymer and Column 2 with molecular sieve. The sample loop is loaded in Position A. When the valve is switched, the loop contents are sent onto Column 1. As the inorganic gases and methane leave Column 1 and enter Column 2, the valve is returned to Position A, reversing the column sequence. COz now leaves Column 1, becoming the first peak.The inorganics and methane are separated by the mole sieve and pass through the porous polymer column to the detector. |

|

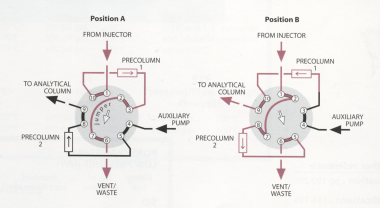

| 10 PORT COLUMN

SWITCHING Sample Enrichment (Cleanup) Using Dual Precolumns Sample is injected by a separate injector onto one of two precolumns (stripper). Early eluting components vent at port 6 while components of interest are retained on the stripper. When the valve is switched, a new injection is made onto the second stripper while components retained on the first stripper are backflushed onto the analytical column at port 9. An auxiliary pump at port 4 is required. |

|

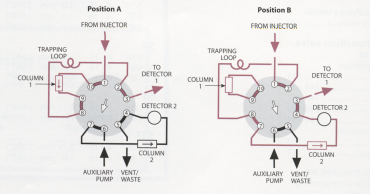

| 10 PORT COLUMN

SWITCHING Heart Cut Trapped in a Loop and Injected onto a Second Column Sample is injected (using a separate injector) onto an analytical column. Early eluting components (front cut) pass through a trapping loop and are detected (at port 3). The valve is then switched, and the center (or heartcut) which was retained in the trapping loop is injected onto the second column to the detector (at port 4). Late eluting components (end cut) are trapped on the first column. When the valve is switched again, the end cut passes through the trapping loop to the first detector, completing the analysis. |

|